A dilatation seal, also known as an expansion joint or expansion seal, is a specialized component used in various engineering and construction applications to accommodate the movement and expansion of structures, equipment, or materials caused by factors such as temperature variations, seismic activity, settling, and more. These seals are designed to prevent or mitigate damage, maintain structural integrity, and enhance the overall safety and performance of the systems they are installed in.

Here’s a detailed description of dilatation seals:

- Function:

Dilatation seals primarily serve the purpose of bridging gaps and accommodating relative movement between two adjacent structural elements or surfaces. They prevent the transfer of stress, loads, and vibrations, which can otherwise cause structural damage or failure. - Types:

Dilatation seals come in various forms to suit different applications, including:

- Expansion Joints: Used in buildings, bridges, and other civil engineering structures to absorb thermal expansion and contraction.

- Pipe Expansion Joints: Installed in pipelines to absorb vibrations, thermal expansion, and misalignment.

- Architectural Joints: Employed in architectural designs to create aesthetically pleasing gaps while accommodating structural movement.

- High-Temperature Expansion Joints: Used in industrial settings to handle extreme temperature variations.

- Isolation Joints: Prevent the transfer of vibrations between adjacent sections of a structure, such as in a hospital operating room.

- Materials:

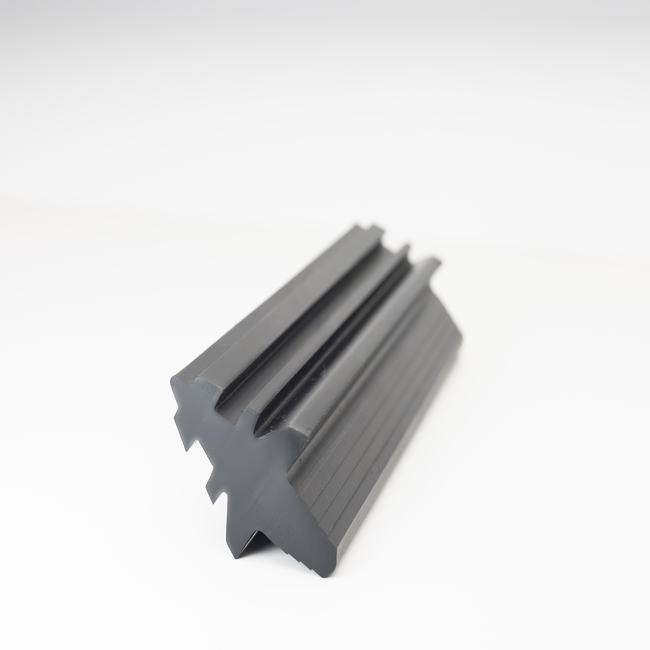

Dilatation seals are manufactured from a variety of materials, depending on the application. Common materials include rubber, neoprene, metal, fabric, composite materials, and various polymer-based compounds. The choice of material depends on factors like the environment, temperature, and the specific type of movement to be accommodated. - Design:

The design of dilatation seals is crucial to their performance. They often feature a flexible, accordion-like or bellows structure, which allows them to expand and contract while maintaining a watertight or airtight seal. Some designs incorporate reinforcement elements like metal frames or flanges for added strength and stability. - Installation:

Proper installation is essential for the effective performance of dilatation seals. They are typically installed in gaps or spaces between structural elements, with careful attention to alignment and the use of appropriate fasteners. The installation process varies depending on the type of seal and the specific application. - Benefits:

- Preventing Structural Damage: Dilatation seals help prevent cracks, leaks, and damage caused by the expansion and contraction of materials.

- Enhancing Safety: In infrastructure like bridges and buildings, expansion joints improve safety by reducing the risk of structural failure during temperature fluctuations or seismic events.

- Minimizing Noise and Vibration: They dampen vibrations and noise caused by machinery, traffic, or other sources, contributing to a more comfortable and quieter environment.

- Aesthetics: Architectural expansion joints can be designed to blend with the overall aesthetics of a structure, ensuring a pleasing visual appearance.

- Maintenance:

Dilatation seals require regular inspection and maintenance to ensure they remain effective. This may involve cleaning, lubrication, and periodic replacement, especially in high-stress environments. - Applications:

Dilatation seals are used in a wide range of industries and applications, including:

- Civil engineering and construction

- Infrastructure projects (bridges, tunnels, highways)

- HVAC systems

- Industrial facilities

- Aerospace and automotive

- Shipbuilding

- Oil and gas pipelines

- Architectural design and construction

In summary, dilatation seals play a critical role in maintaining the integrity, safety, and performance of various structures and systems. They come in different forms, are made from various materials, and are designed to accommodate movement and expansion while preventing damage and maintaining the desired function and aesthetics of the application. Proper installation and maintenance are essential for their long-term effectiveness.